The scientific objectives of the EOSMD research axis aim to develop design and optimization methods of mechanical systems that are compatible with sustainable development taking into account the large diversity of environmental, social and economical impacts involved, as well as the more and more complex nature of the systems under study (power production systems that are interconnected, sustainable mobility, sustainable habitat …). This leads to two fields of research:

- Eco-design of mechanical systems

- Optimization of complex sustainable systems.

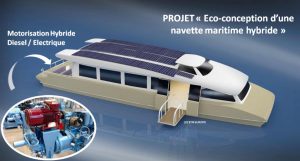

Project of maritime hybrid shuttle

- Eco-design of mechanical systems: the eco-design of mechanical systems raises scientific questions related to the improvement of each main life-cycle stage of a system ( extraction + fabrication + distribution, usage, end-of-life).

- Regarding the end-of-life stage, the reduction of environmental impacts requires the development of new data bases, methods and concepts in order to identify the strategies for end of life (recycling, re-manufacturing, upgradability, re-use,..) of system components and modules and their optimization at the global system level (see Equipment for the study of product disassembly).

- Regarding the use phase, the eco-design of mechanical systems cannot be achieved without taking into account the actual behavior of users and their diversity of usage. To reach an optimal environmental performance, it is therefore necessary to understand (see Equipment for analysis of eco-usages) and correct usage excesses (that cause over-impacts) either through technical choices of design that prohibit these excesses, or through the addition of eco-feedback modules to influence the behavior of users. The difficulty resides in the fact that one must address a large panel of users (presenting very different environmental sensitivities) and that correcting modules must avoid the occurrence of more environmental impacts that the ones issued from their production.

- Regarding the extraction+fabrication+distribution phase, studies must be carried out on new production technologies. We focus on additive manufacturing technologies(see equipment of rapid prototyping). Additive manufacturing is a priori an ecological process in that it allows material deposition only where it is necessary. This reduction of transported material mass is crucial in transportation or autonomous systems because it can lead to a downsizing of the whole system, and therefore improve the environmental performance. However these benefits come together with a set of constraints (sophistication of material, losses due to the fabrication of supports, power of fabrication … ) that translate into an increase of environmental impacts.

- Optimization of complex sustainable systems

- The systems that are designed by engineers become more and more complex ; hence their technical, economical and environmental optimization cannot rely on a simple design iteration approach. We investigate for four years the optimization method based on the principle of constraint satisfaction since it allows to reverse the design problem by identifying the values of design parameters (be they defined as discrete or continuous variables) that allow satisfying the defined objectives. The challenge is to be able to formalize the environmental constraints that are associated to the life cycles of a system, and to couple solving algorithms through constraint propagation with life-cycle analysis methods (see Equipment for environmental evaluation). Our research strategy in this field is to first consider the system statically and secondly to take into account the dynamical aspects (evolution of impacts over time due for instance to a modification of the energetic mix throughout the year), the geographical aspects (spatialization of impacts), and finally the consequential aspects.

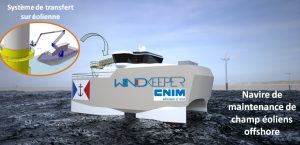

Windkeeper : ship for the maintenance of off-shore wind farms