PhD student

Mail : classope134 (at) etud.univ-tln.fr

Linkedin : Cristiam Javier Lasso Perdomo | LinkedIn

Bio

Research

Thesis topic: Architectural exploration method for an optimized helicopter structure obtained by Additive Manufacturing

Thesis Director: Dominique MILLET

Co-author : Myriam ORQUERA

Keywords: Additive manufacturing – 3D printing – Multi-physics design – Topological optimization – Design methodology – Large volume metal printing – L-PBF (Laser Powder Bed Fusion)

Designing a new aircraft requires setting up different teams, each one working on a subsystem (structure, propulsion unit, etc.) to achieve a system that optimizes both the performance of use (weight, speed, comfort, etc.), production constraints (cost, production speed, quality, etc.), maintenance requirements (disassembly, reliability, etc.) and end of life constraints (recycling, remanufacturing, upgrading, etc.). The diversity of systems and their operating parameters is an obstacle to the improvement and optimization of the overall design of a device.

If we focus on the structure of a helicopter, we see that it is made of either metallic or composite components. The possible improvements on the design of structures present, with conventional production technologies, less and less potential especially on the mass criterion (Courteau, 2013; Dgac, 2019). The gain on this criterion allows a helicopter to be more efficient, more economical in terms of energy resources, but also to meet environmental constraints. This choice of material/process combination also has a strong influence on production costs and rates, particularly because of the many steps involved, which require specific tooling and advanced technical know-how.

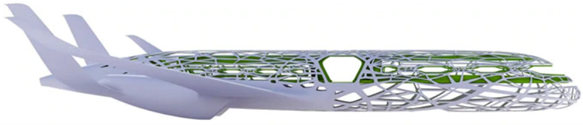

Metal Additive Manufacturing (AM) is a process of manufacturing parts by fusion of a powder bath or by material deposition that has acquired over the last ten years the status of “industrial” technology, due to the diversity of materials that can be used (….) and the robustness of the machines currently on the market, integrating in particular means of control (Gisario et al., 2019; Haleem & Javaid, 2019), means of post-processing (Williams & Butler-Jones, 2019). These AF technologies differ from conventional processes that must deform a billet (forging) or remove material (machining) or pour material into a mold (casting) … However, FA allows us to get closer to design methods using composite materials by positioning the “right Material in the right Place, in the right Direction and in the right Quantity”. The resulting shapes can be extremely complex and can, for example, integrate structural functions with fluid flow and support functions in the same part.

The design method for AF differs from that used for conventional processes (PIPAME, 2017). The different steps are represented by Figure 3 in which the OPTIMIZATIONS parts are very interesting in the aeronautical domain. For example, architectural optimization (Ren & Galjaard, 2015) will optimize the position of the elements, functional optimization will allow adding functions (Campbell et al., 2013; Thompson et al., 2016) in the subsystems and finally topological optimization (Bendsøe, 1995; Tomlin & Meyer, 2011) allows obtaining a gain in mass while respecting the mechanical strength constraints.

The main objective of this thesis is to propose an architectural exploration method for a helicopter structure obtained by Additive Manufacturing in order to define the optimal cutting of this structure. This method will have to integrate the optimizations from a functional, architectural and performance point of view. For that a multi physical study is envisaged (mechanical, thermal, aerodynamic…) focused on the global structure of the vehicle (excluding the engine).

This design method will have to take into account functional constraints (for example the largest possible glazed surface, integration of functions), mechanical constraints (140 load cases) and also manufacturing constraints (“cutting” the main structure into sections for example), maintenance and end of life constraints.

The research program of this thesis includes 6 main steps:

- Study of the field of the constraints of design of a helicopter allowing to establish criteria of performances to evaluate the architectures;

- Study of the field of possibilities of the metallic Additive Manufacturing in order to clarify the granularity of the cutting of the system “structure”;

- Preliminary analysis of the problem in order to define the limits of the “structure” system on which the study will focus;

- First experimental part aiming at carrying out topological optimizations on the whole structure previously defined with various optimization criteria; this leading to various proposals of preliminary cuttings (Dpi) potentially relevant;

- Second experimental part aiming at carrying out topological optimizations on each subset of each DPi; The evaluation of the synthesis of these optimizations allowing to establish a hierarchy of the DPi and a comparison with the traditional cutting;

- Proposal of an architectural exploration method for an optimized helicopter structure obtained by Additive Manufacturing.

Teaching

- 2021-2022 : 40h of the course Design of Mechanical Structures (DISM) at SEATECH

- 2021-2022: 12 hours of practical CATIA 3D modelling at SEATECH