The COSMER lab participated in the IROS conference at Abu Dhabi in Oct. 2024, where Charly Péraud presented his work described in two papers:

IMU-based Monitoring of Buoy-Ballast System through Cable Dynamics Simulation

Workshop ROMADO: Cable Lobe Detection in a ROV/USV Tethered System Using IMUs and

Compliant Buoy-Ballast Equipment.

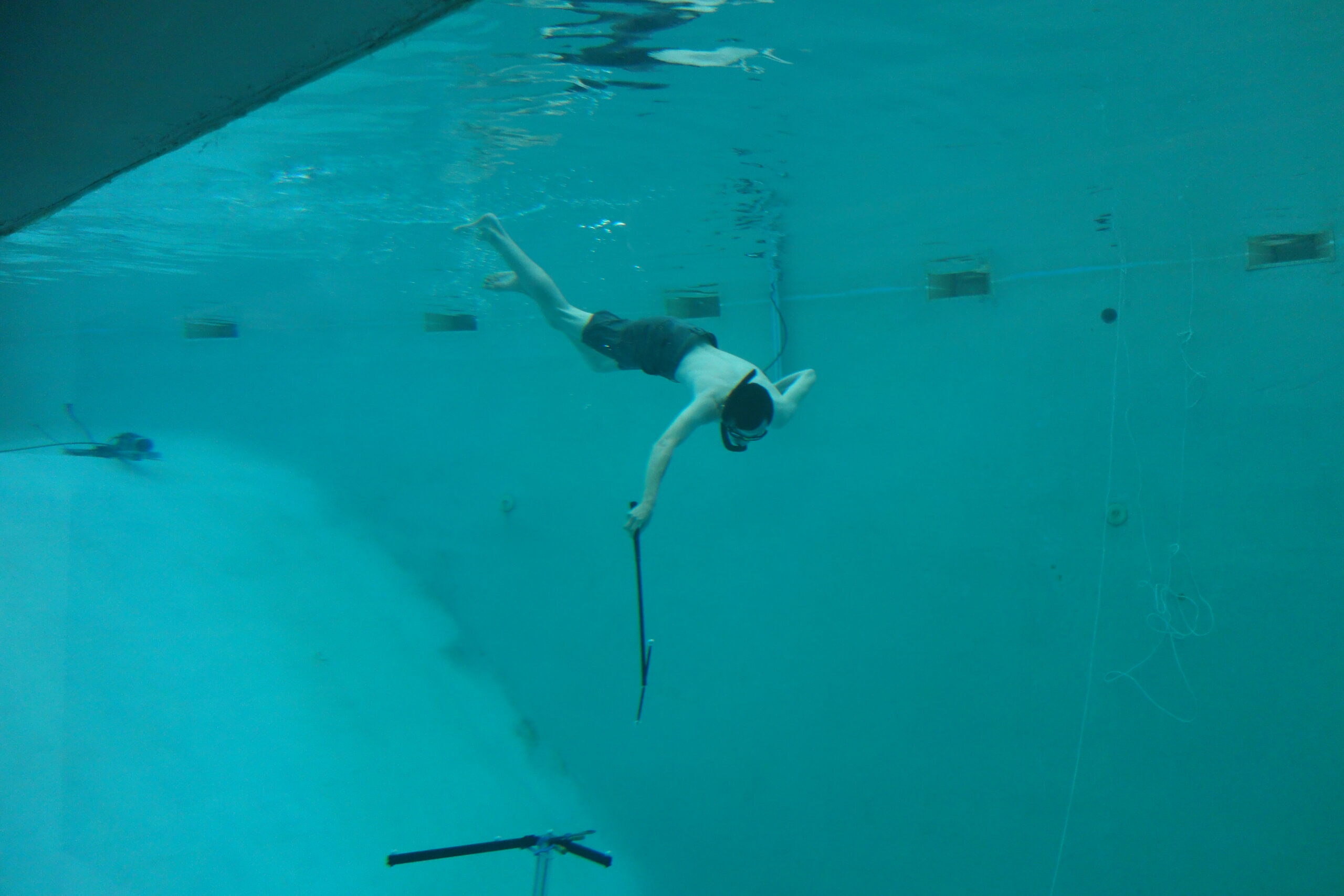

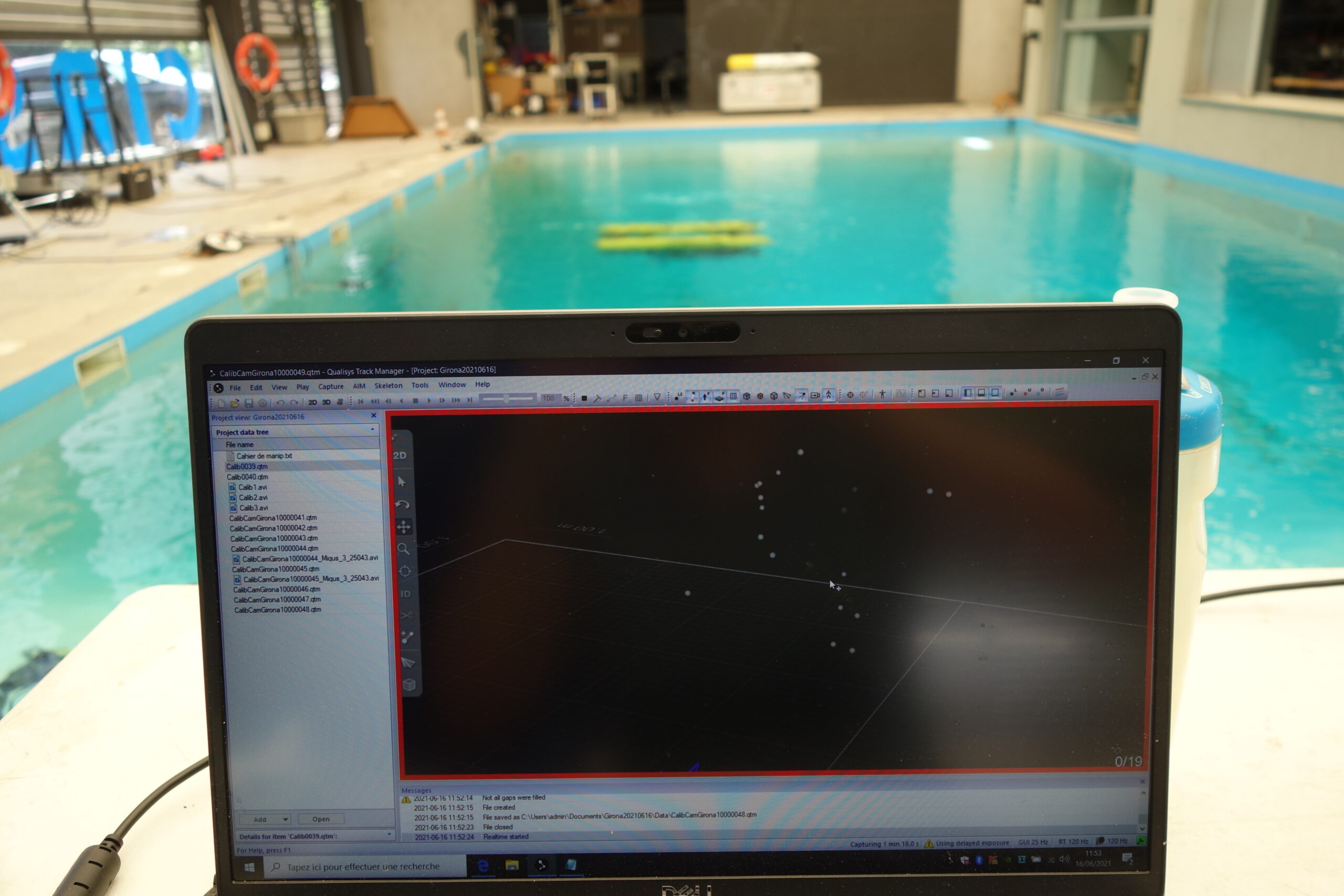

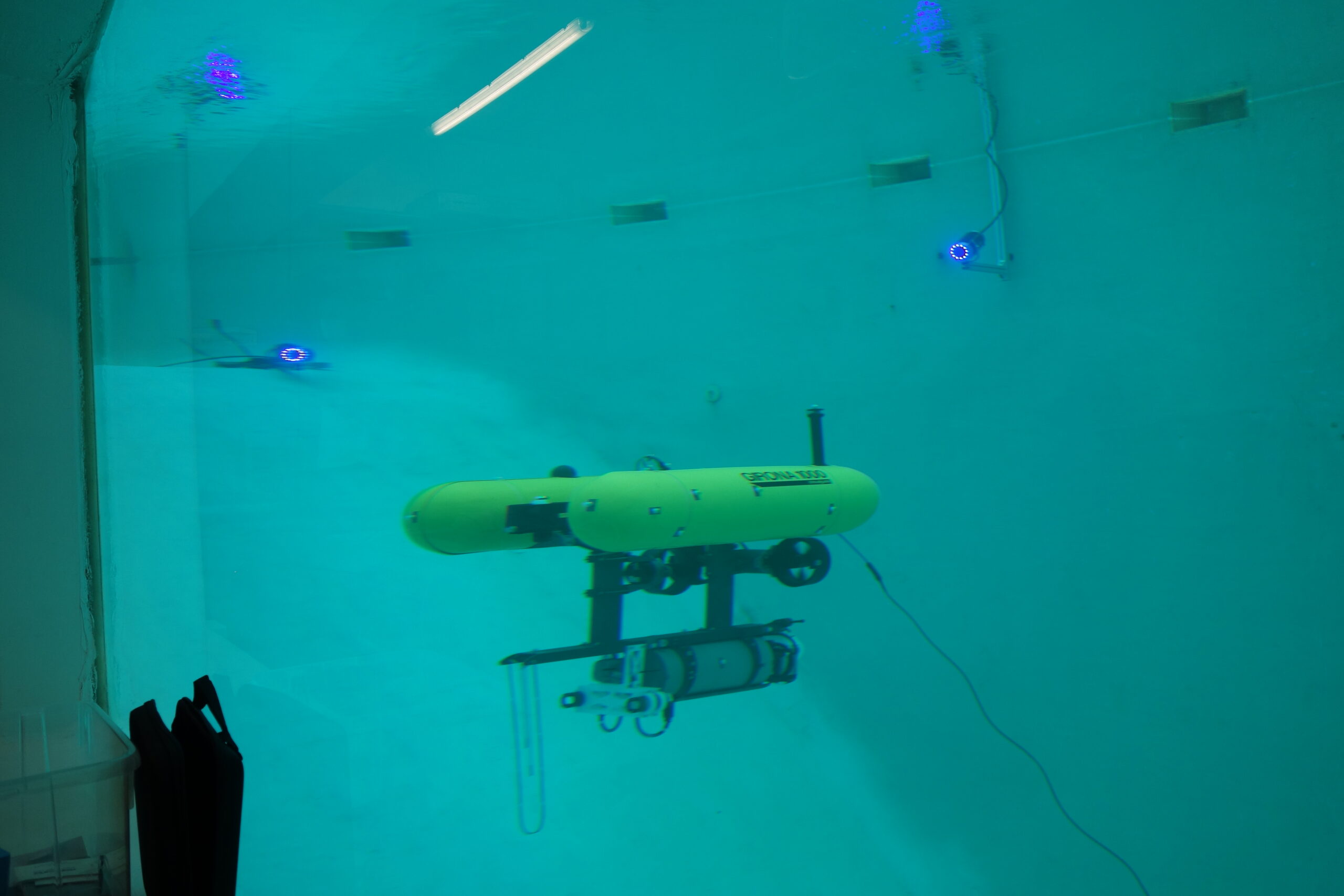

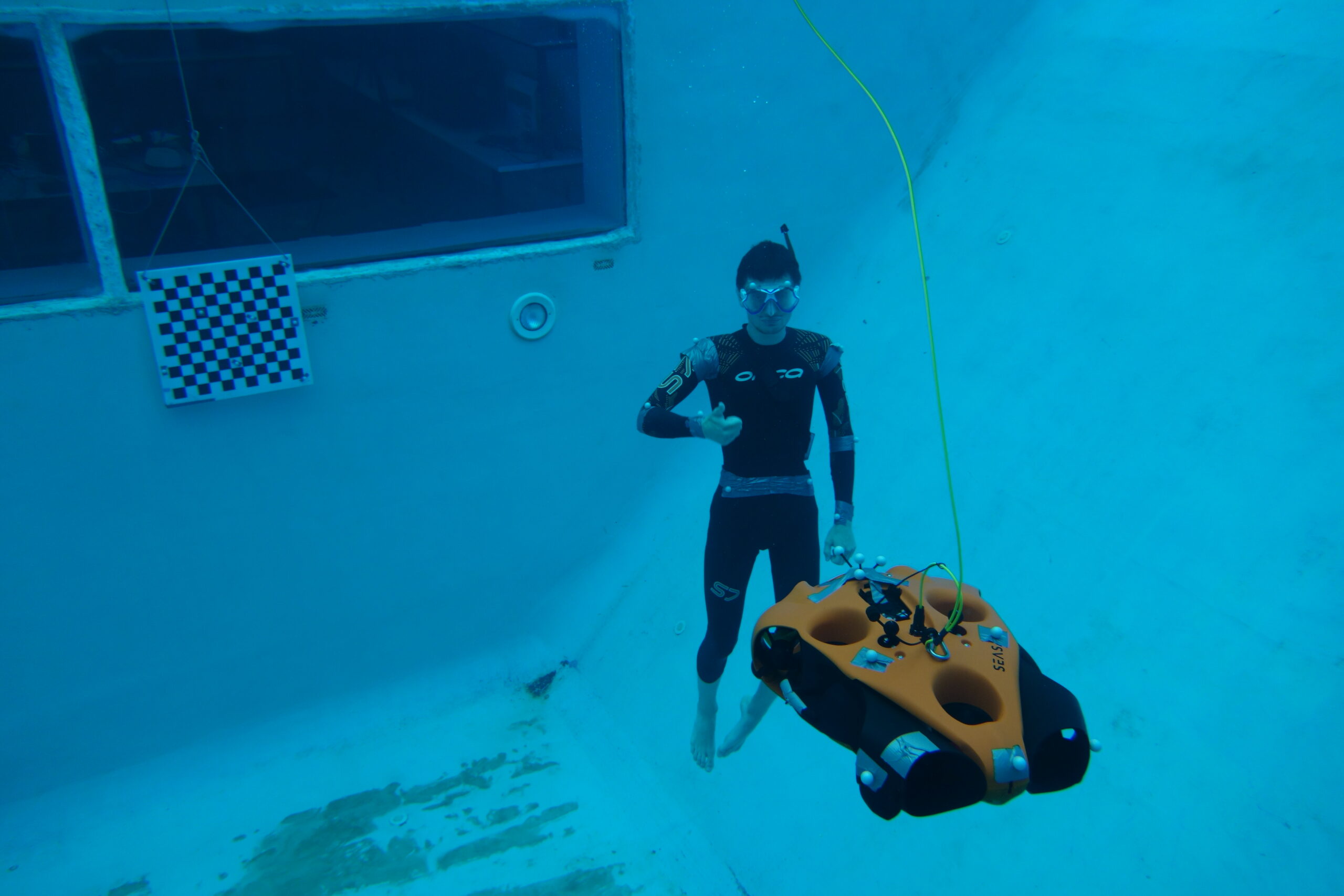

From the 2nd to the 6th of March, a team of researchers and students of the Université de Toulon have been carrying out experiments at the facilities of the CIRS.

From the 2nd to the 6th of March, a team of researchers and students of the Université de Toulon have been carrying out experiments at the facilities of the CIRS.